Combined deposition and etch modules’ system of cluster type for advanced electronics uGmni-200, 300

Home / PRODUCTS / Vacuum Equipments / Sputtering System / Combined deposition and etch modules’ system uGmni-200, 300

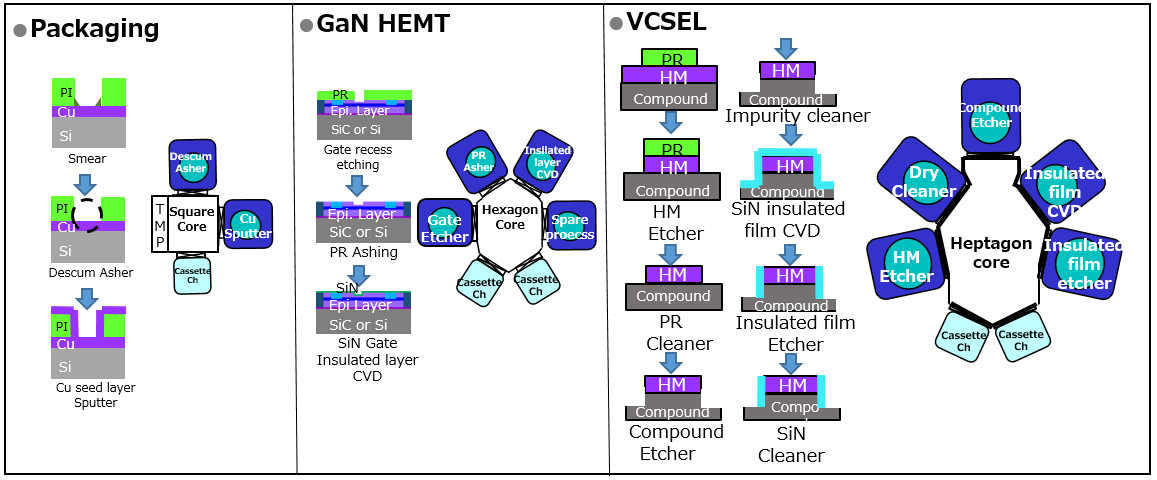

uGmni is to equip with a variety of different process modules on the same transfer core which makes reducing spare parts by adopting the same common parts as much as possible as well as improves usability with the same operation panel between these different modules. This improves further efficiency for manufacturing process of advanced electronics.

Features

- Multi types of Sputter, Etcher, Asher&PE-CVD modules can be equipped.

- All types of above modules are made by ULVAC.

- Up to Φ300㎜ wafer is applicable.

applications

(Examples follow)

- Power device Seed & Metal layer Sputtering

- MEMS sensor PZT Sputtering & Etching

- Opt. device VCSEL Etching

- Packaging Descum Ashing

- Communication Insulated film PE-CVD and Etching

specifications

*Not only below, if require others please contact us Below numbers depend on Spec.

| Ultimate pressure | Stage temp. | Within wafer unif. (Ref. only) | Use | Plasma source | |

| Sputter | <6.7E-5Pa | Cold(Cooling ability T.B.D)~700℃ | ±1~5% | Metal, dielectric film, insulated film | DC |

| Pulse DC | |||||

| RF | |||||

| Etcher | <1.0E-3Pa | -20~200℃ | <±5% | Metal, dielectric film, insulated film, Si types | CCP |

| ISM (Inductively Super Magnetron、ULVAC Patent) | |||||

| NLD (Neutral Loop Discharge、ULVAC Patent) | |||||

| Asher | <0.7Pa | 50~250℃ | ±5% | Descum, desmear, removing sacrified layer, surface treatment, removing PR and PI etch | Microwave |

| 20~80℃ | Microwave+CCP | ||||

| PE-CVD | <2Pa | 60~400℃ | <±1% | Insulated film(SiNx,SiOx) | Anode coupling |

| Dual Frequency |

System configurations

Varieties of modules can be equipped(Examples follow)

关注我们

Zalo

ZALO 0988248567

联系我们

ULVAC Vietnam Representative Office

29/11/100 Le Duc Tho Street, An Nhon Ward,

Ho Chi Minh City, Vietnam

5/5/42 Thanh Binh Street, Le Thanh Nghi Ward,

Hai Phong City, Vietnam