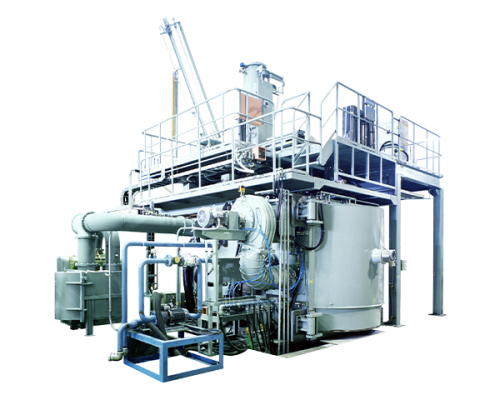

Vacuum Induction Melting Furnaces FMI Series

Home / PRODUCTS / Vacuum Equipments / Vacuum Furnace System / Vacuum Induction Melting Furnaces FMI Series

Since the first unit was produced in 1957, ULVAC has delivered over 200 vacuum induction melting furnaces to customers in Japan and around the world. These furnaces are contributing to a wide range of industry applications such as specialized steel, electronics materials and new materials. They have been used in developing new technologies such as high-vacuum degassing and refining using cryopanels, and multi-element alloys created by single-direction agitation systems. ULVAC can also provide equipment lines and production technology for rare-earth magnet manufacturing.

Features

- Cryopanels create outstanding degassing effect.

- Large volumes of activated metal can be added and controlled.

- Outstanding ingot cleaning

- Single-direction agitation creates outstanding component uniformity

- Rapid heating, for outstanding operability

- Selectable casting type:black and strip casting

applications

- Fe-base alloys : Mechanical tools (hob cutters, pinions, cutting tools), dies, bearing steel

- Rare-earth metals : Magnets (Nd-Fe-B, Sm-Co)

- Ti alloys : Shape-memory alloys, hydrogen-absorbing alloys

- Precious metals: Bonding wires, Au, Pt, thermocouples, electric contact materials, dental products, ornaments

- Ni-base alloys : Heat-resistant steel, corrosion-resistant materials, electrical part materials, permalloys

- Al : Bonding wires, lead frames, sputter targets

- Cu : Electric contact materials, lead frames

- Cr : Sputter targets

specifications

| Model | FMI-1 (batch type) |

| Melted materials | Iron, nickel, iron-base alloys or nickel-base alloys |

| Standard melting volume | 5Kg to 100kg |

| Output/frequency | 25kW/10kHz to 100, kW/1kHz |

| Standard time until melting (thermal furnaces) | 30 to 60 minutes |

| Pressure after melting (standard) | 1.3×10-1Pa(10-3Torr) |

| Power supply for melting (3φ, 440 V, 50/60 Hz) | About 25 to 120 kVA |

| Operation power supply (3φ, 200/220 V, 50/60 Hz) | About 10 to 25 kVA |

| Cooling water (0.3 MPaG (3 kg/cm2G)) | About 3 to 12 tons/hour |

| Compressed air (0.6 MPaG (6 kg/cm2G)) | Some |

| Installation area | 6 x 5 x 3 to 7 x 7 x 5 (L x W x H; m) |

| Model | FMI-2(semi-continuous type) |

| Melted materials | Iron, nickel, iron-base alloys or nickel-base alloys |

| Standard melting volume | 100Kg to 1000Kg |

| Output/frequency | 100kW/1kHz to 500kW/500kHz |

| Standard time until melting (thermal furnaces) | 60 to 120 minutes |

| Pressure after melting (standard) | 1.3 x 10-1Pa(10-3Torr) |

| Power supply for melting (3 f, 440 V, 50/60 Hz) | About 120 to 800 kVA |

| Operation power supply (3f, 200/220 V, 50/60 Hz) | About 30 to 160 kVA |

| Cooling water (0.3 MPaG (3 kg/cm2G)) | About 15 to 35 tons/hour |

| Compressed air (0.6 MPaG (6 kg/cm2G)) | About 10 to 20 liters/minute |

| Installation area | 11 x 8 x 5 to 17 x 14 x 8 (L x W x H; m) |

关注我们

Zalo

ZALO 0988248567

Line Add

联系我们

ULVAC Vietnam Representative Office

29/11/100 Le Duc Tho Street, Ward 7, Go Vap District Ho Chi Minh City, Vietnam

5/5/42 Thanh Binh Street, Hai Duong Province, Vietnam