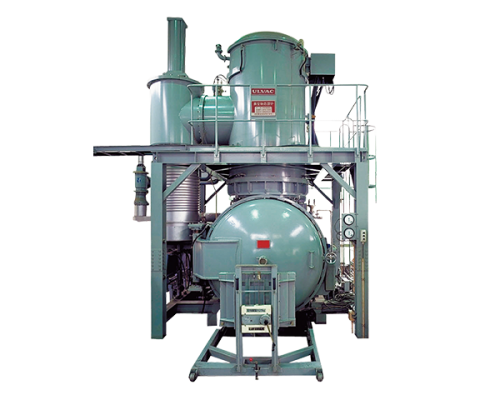

Vertical Type Vacuum Heat Treatment Furnace FHV Series

Home / PRODUCTS / Vacuum Equipments / Vacuum Furnace System / Vertical Type Vacuum Heat Treatment Furnace FHV Series

FHV series are used for various purposes such as quenching, tempering and brazing of various metals. Vertical two-chamber configuration which consists of heating chamber + preparation/cooling contributes to space saving by adopting elevation mechanism. Temperature data from heating process to cooling process can be seamlessly recorded for quality control of products.

Features

- Maximum temperature 1350ºC, Operation temperature 800 to 1150ºC

- Temperature uniformity is within ±5ºC at 1150ºC

- Keeping the heating chamber in vacuum for high quality and repeatability of products.

- Optional rotating cooling mechanism is suitable to process long products such as cutting tools.

- Thermocouple can be directly set on processing products for historical data of products temperature from heating to cooling as precise quality control.

applications

- Quenching, Tempering : various machine parts, parts for air plane.

- Brazing : Heat exchanger, machine parts, parts for air plane, vacuum interception.

specifications

| System | 45 | 60 | 90 | 120 | Remarks | ||

| Performance | |||||||

| Size | Uiform hot zone (㎜) | Dia meter | 450 | 600 | 900 | 1200 | |

| Height | 450 | 600 | 900 | 1200 | |||

| Loading capacity (㎏) | 180 | 320 | 900 | 1200 | including tray’s weight | ||

| Temperature | Max. temperature | 1350ºC | |||||

| Operation temperature | 800 to 1150ºC | ||||||

| Temperature uniformity | 1150ºC ± 5ºC | Five points measurement at no load | |||||

| Cooling | Gas cooling | 93kPa | 30 minutes or less | from 1150ºC to 150ºC when standard specimen is charged. | |||

| 190kPa | 20 minutes or less | ||||||

| Vacuum | Ultimate vacuum | 10-1Pa(10-3Torr)order.(High vacuum 10-3Pa (10-5 Torr) order is option) | At degassed and empty conditions | ||||

| Operating pressure | 133 to 13Pa (1〜10-1Torr) | ||||||

| Pump-down time | 10 minutes or less | 15 minutes or less | from the atmosphere to 6.5Pa ( 5×10-2Torr) at no load | ||||

| Leak rate (Pa・m3/S) | 3×10-4 | 4×10-4 | 5×10-4 | by pressure rise method | |||

| Utility | |||||||

| Power requirement (kVA) | GH* | 65 | 101 | 209 | 278 | AC 200/ 220V 90& 120 type 400/ 440V 50/ 60Hz 3φ (Primary power requirement) | |

| Cooling water requirement (m3 /hr) | GH* | 3 | 5 | 9 | 16 | Pressure 2.5/cm2G (250KPa) Temperature 30ºC or less ※25ºC or less, with oil diffusion pump | |

| Compressed air requiremen (Nm3 /min) | Some | 700KPa | |||||

| Carrier gas requirement (L/min) | 1.5 | 2.2 | 7.2 | 10 | N2gas (N.T.P) | ||

| Cooling gas requirement (m3/times) | 1.8 | 3 | 6 | 10 | N2 gas (N.T.P) | ||

| Floor space requirement (m2) | 2chamber type GH* | 3.4×5.1 | 4×6.3 | 6×9 | 7×10 | W×L | |

| 3.5× 2.3 | 4× 2.6 | 5× 3.5 | 6× 4 | H×D | |||

* Chamber used:P=Preparation(loading/unloading)Chamber,H=Heating Chamber,G=Gas Cooling Chamber,L=Oil Cooling Chamber

关注我们

Zalo

ZALO 0988248567

Line Add

联系我们

ULVAC Vietnam Representative Office

29/11/100 Le Duc Tho Street, Ward 7, Go Vap District Ho Chi Minh City, Vietnam

5/5/42 Thanh Binh Street, Hai Duong Province, Vietnam