HỆ THỐNG KẾT HỢP MODUL ETCH VÀ THÀNH PHẦN UGMNI

Home / Sản phẩm / Thiết bị chân không / Hệ thống phún xạ chân không / HỆ THỐNG KẾT HỢP MODUL ETCH VÀ THÀNH PHẦN UGMNI

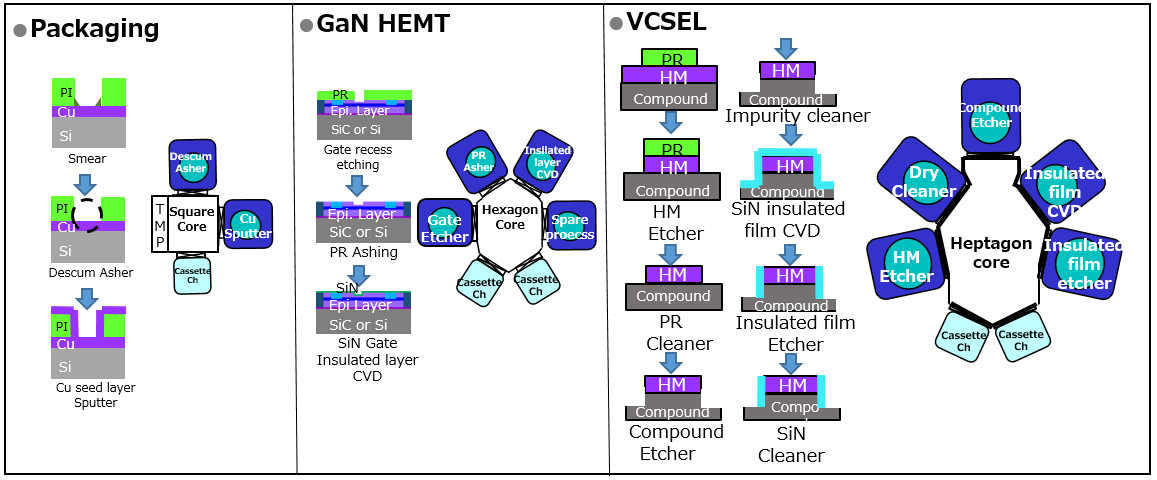

uGmni là trang bị nhiều mô-đun quy trình khác nhau trên cùng một lõi chuyển, giúp giảm thiểu phụ tùng thay thế bằng cách sử dụng các bộ phận chung giống nhau nhiều nhất có thể cũng như cải thiện khả năng sử dụng với cùng một bảng điều khiển giữa các mô-đun khác nhau này. Điều này cải thiện hiệu quả hơn nữa cho quá trình sản xuất thiết bị điện tử tiên tiến.

ĐẶC ĐIỂM

- Có thể trang bị nhiều loại mô-đun Sputter, Etcher, Asher & PE-CVD.

- Tất cả các loại mô-đun trên đều do ULVAC thực hiện.

- Có thể áp dụng tấm wafer lên đến Φ300㎜.

ỨNG DỤNG

(Examples follow)

- Thiết bị điện Seed & Lớp kim loại phún xạ

- Cảm biến MEMS PZT Sputtering & Etching

- Opt. thiết bị VCSEL khắc

- Bao bì Descum Ashing

- Truyền thông Màng cách nhiệt PE-CVD và khắc

bảng tiêu chuẩn

* Không chỉ bên dưới, nếu có những yêu cầu khác vui lòng liên hệ với chúng tôi. Các số bên dưới dựa vào bảng tiêu chuẩn.

| Ultimate pressure | Stage temp. | Within wafer unif. (Ref. only) | Use | Plasma source | |

| Sputter | <6.7E-5Pa | Cold(Cooling ability T.B.D)~700℃ | ±1~5% | Metal, dielectric film, insulated film | DC |

| Pulse DC | |||||

| RF | |||||

| Etcher | <1.0E-3Pa | -20~200℃ | <±5% | Metal, dielectric film, insulated film, Si types | CCP |

| ISM (Inductively Super Magnetron、ULVAC Patent) | |||||

| NLD (Neutral Loop Discharge、ULVAC Patent) | |||||

| Asher | <0.7Pa | 50~250℃ | ±5% | Descum, desmear, removing sacrified layer, surface treatment, removing PR and PI etch | Microwave |

| 20~80℃ | Microwave+CCP | ||||

| PE-CVD | <2Pa | 60~400℃ | <±1% | Insulated film(SiNx,SiOx) | Anode coupling |

| Dual Frequency |

Cấu hình hệ thống

Nhiều loại mô-đun có thể được trang bị (Ví dụ sau)

Follow us

Zalo

ZALO 0988248567

Line Add

Contact Us

ULVAC Vietnam Representative Office

29/11/100 Le Duc Tho Street, Ward 7, Go Vap District Ho Chi Minh City, Vietnam

5/5/42 Thanh Binh Street, Hai Duong Province, Vietnam