LÒ NUNG CHẢY CẢM ỨNG CHÂN KHÔNG DÒNG FMI

Home / Sản phẩm / Thiết bị chân không / LÒ XỬ LÝ NHIỆT CHÂN KHÔNG / LÒ NUNG CHẢY CẢM ỨNG CHÂN KHÔNG DÒNG FMI

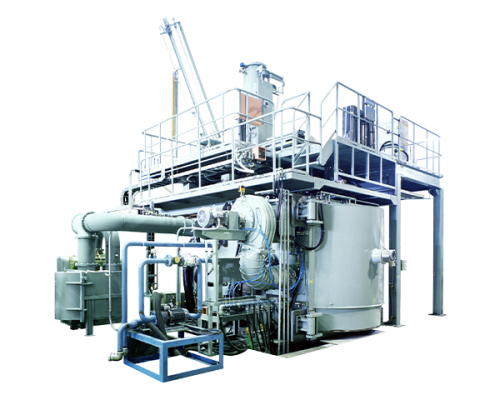

Lò nung chảy cảm ứng chân không, Kể từ khi tổ máy đầu tiên được sản xuất vào năm 1957, ULVAC đã cung cấp hơn 200 lò nung chảy cảm ứng chân không cho khách hàng ở Nhật Bản và trên thế giới. Những lò này đang đóng góp vào một loạt các ứng dụng công nghiệp như thép chuyên dụng, vật liệu điện tử và vật liệu mới. Chúng đã được sử dụng để phát triển các công nghệ mới như khử khí chân không cao và tinh chế bằng cách sử dụng các tấm cryo và các hợp kim đa nguyên tố được tạo ra bởi các hệ thống kích động một hướng. ULVAC cũng có thể cung cấp dây chuyền thiết bị và công nghệ sản xuất để chế tạo nam châm đất hiếm.

ĐẶC ĐIỂM

- Cryopanels tạo ra hiệu ứng khử khí vượt trội.

- Khối lượng lớn kim loại hoạt tính có thể được thêm vào và kiểm soát.

- Làm sạch thỏi vượt trội

- Sự khuấy động một hướng tạo ra sự đồng nhất của các thành phần vượt trội

- Làm nóng nhanh chóng, cho khả năng hoạt động vượt trội

- Loại đúc có thể lựa chọn: đen và đúc dải

ỨNG DỤNG

- Kim loại đất hiếm: Nam châm (Nd-Fe-B, Sm-Co)。

- Hợp kim Ti: Hợp kim nhớ hình dạng, hợp kim hấp thụ hydro

- Kim loại quý: Dây liên kết, Au, Pt, cặp nhiệt điện, vật liệu tiếp xúc điện, sản phẩm nha khoa, đồ trang tríHợp kim cơ sở

- Ni: Thép chịu nhiệt, vật liệu chống ăn mòn, vật liệu phần điện, vật liệu cố định

- Al: Dây liên kết, khung dẫn, mục tiêu phún xạ

- Cu: Vật liệu tiếp xúc điện, khung chì

- Cr: Mục tiêu giật gân

BẢNG TIÊU CHUẨN

| Model | FMI-1 (batch type) |

| Melted materials | Iron, nickel, iron-base alloys or nickel-base alloys |

| Standard melting volume | 5Kg to 100kg |

| Output/frequency | 25kW/10kHz to 100, kW/1kHz |

| Standard time until melting (thermal furnaces) | 30 to 60 minutes |

| Pressure after melting (standard) | 1.3×10-1Pa(10-3Torr) |

| Power supply for melting (3φ, 440 V, 50/60 Hz) | About 25 to 120 kVA |

| Operation power supply (3φ, 200/220 V, 50/60 Hz) | About 10 to 25 kVA |

| Cooling water (0.3 MPaG (3 kg/cm2G)) | About 3 to 12 tons/hour |

| Compressed air (0.6 MPaG (6 kg/cm2G)) | Some |

| Installation area | 6 x 5 x 3 to 7 x 7 x 5 (L x W x H; m) |

| Model | FMI-2(semi-continuous type) |

| Melted materials | Iron, nickel, iron-base alloys or nickel-base alloys |

| Standard melting volume | 100Kg to 1000Kg |

| Output/frequency | 100kW/1kHz to 500kW/500kHz |

| Standard time until melting (thermal furnaces) | 60 to 120 minutes |

| Pressure after melting (standard) | 1.3 x 10-1Pa(10-3Torr) |

| Power supply for melting (3 f, 440 V, 50/60 Hz) | About 120 to 800 kVA |

| Operation power supply (3f, 200/220 V, 50/60 Hz) | About 30 to 160 kVA |

| Cooling water (0.3 MPaG (3 kg/cm2G)) | About 15 to 35 tons/hour |

| Compressed air (0.6 MPaG (6 kg/cm2G)) | About 10 to 20 liters/minute |

| Installation area | 11 x 8 x 5 to 17 x 14 x 8 (L x W x H; m) |

关注我们

Zalo

ZALO 0988248567

Line Add

联系我们

ULVAC Vietnam Representative Office

29/11/100 Le Duc Tho Street, Ward 7, Go Vap District Ho Chi Minh City, Vietnam

5/5/42 Thanh Binh Street, Hai Duong Province, Vietnam